EASI-SPAN BUILDINGS FOR WATER & WASTE TREATMENT BUILDINGS

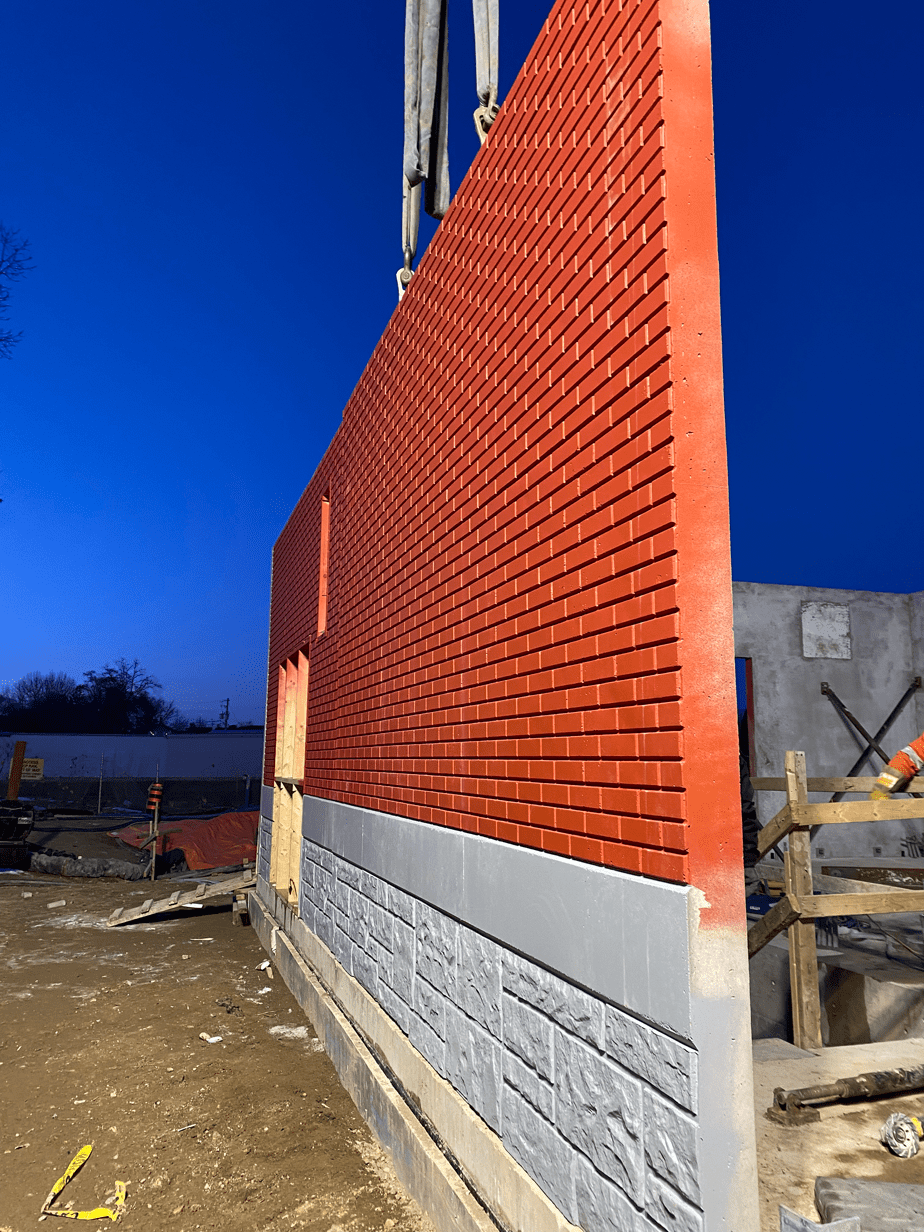

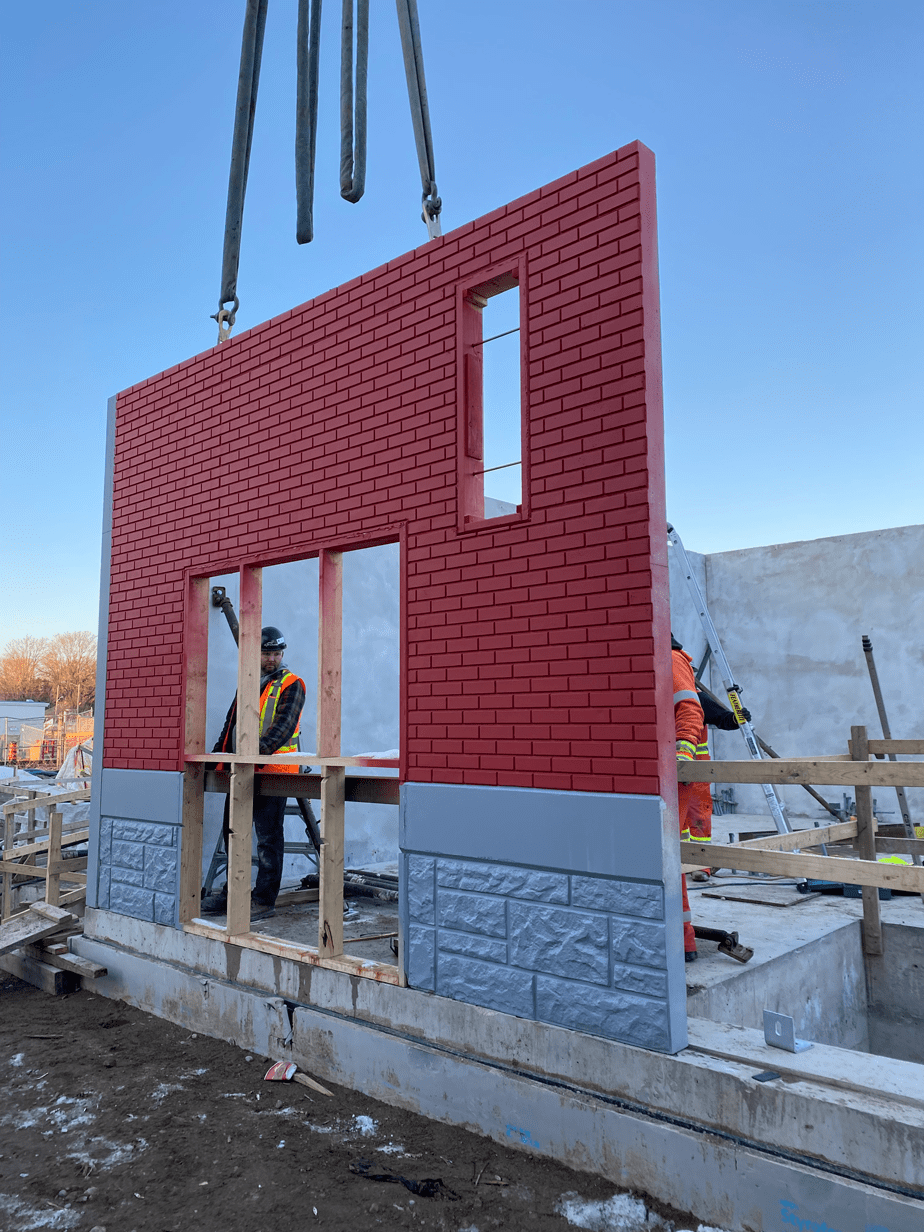

To gain approval from the City, aesthetics were prioritized in the design. Past projects helped to convey this. The City required prior approval for both types of walls. DCI provided detailed engineered and stamped SK drawings of the walls and included photographs of similar installations from previous projects.

The Easi-Span building for this project measured 30’ wide x 30’ long, a large enough footprint to house important monitoring, electrical and mechanical equipment for the pump station.

A single-sourced structure, the Easi-Span building eliminated involvement of multiple trades or vendors such as masons, steelworkers, roofing contractors, or painters. A complete precast building also ensures the longevity of the building as compared to other material types with much shorter lifespans.

The City’s goal of securing the equipment was met. Where Precast offered a level of security during severe weather events, offering a watertight building envelope that protect against strong windstorms or flooding. Additionally, our building designs offer a blast and ballistic protection, tested to UL-752/Test Method 5. The building is not only stronger, but limits the impacts of possible theft or vandalism. Our buildings are more resilient for long-term operations.